(January 2013) – Mobil Vacuoline 100 and Mobilgrease XHP 461, part of ExxonMobil’s comprehensive range of products for primary metals companies , have helped two Russian steel mills to increase productivity, reduce unscheduled downtime and significant financial benefits.

Significant financial savings and performance benefits achieved by switching to high performance lubricants

· Mobil Vacuoline has enabled a Russian steel manufacturer to reduce downtime and save up to $222,000 USD over two years

· Bearing failures at a steel mill eliminated following the introduction of Mobilgrease XHP 461

· Mobil-branded industrial greases and oils have the potential to help steel operators achieve a competitive edge

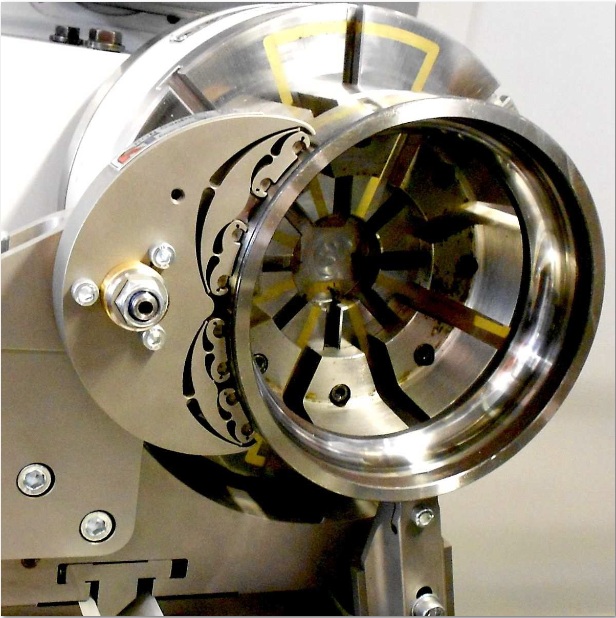

One Russian steel producer reported issues with its SKET 350 rolling mill, with bearing failures and unscheduled downtime occurring as a result of the lubricant in use. The poor water separation capability of the lubricant was causing the bearings in the rolling mill to rust and fail.

Following a recommendation from ExxonMobil engineers, the metallurgical plant switched to Mobil Vacuoline 133 to protect the bearing in its SKET rolling mill.33. This high performance circulating system oil contains high quality base stocks and additives that resist emulsion and sludge, contributing to cleaner systems and filters, as well as helping solid contaminants separate for easy cleaning by centrifuge, filtration or settling. Following the introduction of Mobil Vacuoline, the bearing life was significantly improved with the resulting savings in maintenance and replacement bearings helping to generate cost saving of approximately $222,000 USD.

Alongside its range of high performance industrial oils, Mobil-branded greases have also helped to increase productivity and reduce unscheduled downtime. For example, a hot sheet steel rolling mill in Russia was experiencing problems with bearing failure in the roller bearings cages of its work rolls 2000.

Following an investigation by ExxonMobil engineers, they identified the bearing failures were occurring due to significant water washout of the grease in use, which was leading to corrosion attacking the bearings due the lubricant being unable to sufficiently protect the bearings. To address the problem, ExxonMobil recommended switching to Mobilgrease XHP 461 due to the product’s superior resistance to water washout, excellent rust and corrosion protection and good thermal stability. Following the switch over, lubricant-related bearing failures were eliminated and other benefits such as lower grease consumption were reported, helping cost control.

“With major international sporting events on the horizon, the demand for primary metals in Russia has soared and local manufacturing facilities are constantly looking at ways to boost productivity”, commented Kirill Chervyakov, Industrial Marketing Advisor – EAME, ExxonMobil Lubricants and Petroleum Specialties Company, a division of Exxon Mobil Corporation. “By switching to high performance Mobil Industrial Lubricants operators can look to boost plant output and significantly reduce maintenance costs.

For more information about ExxonMobil’s range of products and services for the primary metals sector, please visit mobilindustrial.com

source: Process & Control Today