EX Tri-layer low maintanence plain bushings has good physical & mechanical properties, also has certainly chemical properties. This material has good machining performance if required.

EX Brief Description

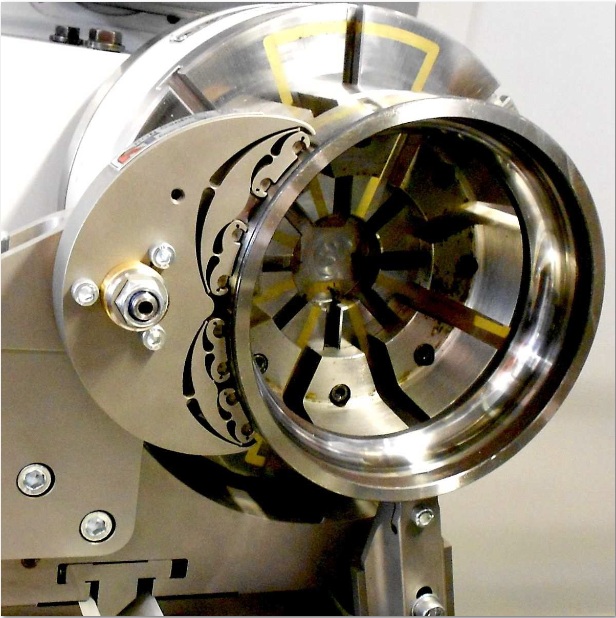

EX tri-layer low maintanence plain bushing have a base of lower carbon steel, onto which a porous bronze layer is sintered. Acetalcopolyer (POM) is impregnated into the intersice of this bronze layer after rolling process completed. Lubrication indents are stamped into this layer. EX has good physical & mechanical properties, also has certainly chemical properties. This material has good machining

|

|

|

1 Self-lub. Layer POM 0.3-0.5mm.

After rolling process completed, POM are filled in intersice of bronze layer, lubrication indents are stamped, which are full of oil grease, which will be removed and transferred on the mating surface, forms a physically lubricating film, which will reduced the firction coe. and protect the mating shaft.

2 Porous bronze layer;

The layer provides bonded strength of self-lub. Layer.

3 Steel Backing

The layer provides load & thermal conductivity

4 Copper / Tin layer.

EX Material Characteristics

| Max. Load Capacity | ||

| Static Load | N/mm2 | 250 |

| Dynamic Load | N/mm2 | 140 |

| Max. Speed | ||

| Pre-Lubricated | m/s | 2.0 |

| Oil Grease Lubrication Continuous Operation | m/s | >2.0 |

| Max. Pv Value | N/mm2 · m/s | 2.8 |

| Coefficient of Friction | μ | 0.05~0.20 |

| Operation Temperature Range | ℃ | -40~110 |

| Thermal Conductivity | W(m · k-1) | 42 |

| Coefficient of Thermal Expansion | λST | 11 · 10K-6 |

※ Initial pre-lubrication at assembly is necessary.

EX Application

EX bushings have been recommended for application involving intermittent operation or boundary lubrication. Base on the unique lubrication-retaining pockets on surface, EX bushings are well suitable for application, where lubricant can not be supplied continuously or repeated. Under the no lubrication, the EX operating life depends on interaction of the specific load, surface velocity and temperature etc. EX bushings can be supplied as machining allowance on POM, it can be machined to Better assembly dimensions after installed into housing.

The following list covers some of the many types of EX bearing applications.

Automotive:

suspension system, suspension joints, king-pin assemblies, automobile driving joint hinges, steering and other linkages, steering and articulation joints, rear chassis hinges etc.

Agricultural Machinery/Equipments:

Gearbox, clutch, kingpin bearings for harvesters, front axle pivot bearings, steering idler box bearings, tractor gears, seeding equipment, etc.

Machine Tool Building Industry:

Grinding machines, milling machines, spindles in drill; Eccentric drive unit in precision grinding machines etc

Other Applications:

Oil gear pumps, support bearings in rotary actuators; variable swash plate trunnion bearings in hydraulic pumps, piston rod guide in hydraulic and pneumatic cylinders; Transfer gearbox for forklift trucks, gearbox and in idler chain sprockets for crane transmissions, car conveyors, worm drive gear, etc.

Contact Details:

Jiashan Epen Bearing Co.,Ltd

No 161 ChengGong Road. Hui Min Street

Jiashan Zhejiang China

PostCode: 314100

T: +86 573 84824388

F: +86 573 84824386

Http: www.cnepen.cn

Email: [email protected]